To be named

Project Supervisor : Teo Shin Jen

The situation

My mom works really hard at a secondary school canteen selling snack to students. I being her son want to alleviate her workload because i see first hand when I am helping her with the store how tough it is to run a small scale canteen stall. Being a computer engineer student at Singapore Polytechnic, I have worked on many IoT project and participate in a few hackathons. I want to create a IoT solution that automate money collection and display the sale data for my mom in a fairly meaningful manner. Being only able to help my mom during Saturdays (external students come in the school for after school lesson), due to my commitments to school. I have identified a few inefficiency that my mom experience when running the store. My goal is to eliminate all or most of the inefficiency for a reasonable price so that my mom has more time to do what she wants. Also, i believe all the small thing should be done by machines, so much time is waste doing nonsense.

The problems

My mom sell snack stuff (eg. nugget, sandwich, coffee, drinks). I not so sure how she runs the store during weekdays where the actual students come, i only am able to help her with the store on Saturdays where external students uses the school facilities. The biggest problem comes when my mom comes home with the money, she has to count the total money sometimes makes me count the money which is an inconvenience. After that she is just tired and sleep for the rest of the day. Partly the reason would probably that she wakes up early for food preparation. From my observation, there is a lot of inefficiency in how she run the store. She has to count money and serve the student while more and more student rush to get their food. Regular students may know the price but new students don't know, which can slow down the process. This handling of money is very inefficient because honestly takes the most time cause you how fumble the coins for change. Basically, i trying to make the money collection more efficient saving her time.

Why am I doing this?

The food items that my mom sells, sell for very little margins. So, it give her little reason to invest into a money counter or a cash register. Also, my mom has this dilemma where she has trouble predicting how much students are going to eat today. Sometimes, she will be able to sell everything but other times she will have tons of leftovers for my me to eat, which is't bad but very unhealthy. The IoT part of this project is to overcome this problem. Sales data can and will be useful for my mom to predict the amount of food to prepare. And also because I can.

The plan

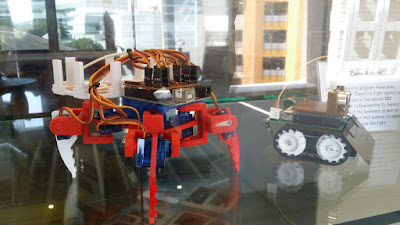

I'm still in the very early stages of the project, I have a lot of things to sort out especially the technology part on money collection. The whole tech will probably be done on arduino (arduino very cheap) or if needed a rasppi.

My mom being technologically-challenged not to mention the students we will need to educate on how to use my solution, I will need my solution to be fairly user-friendly.

To be updated....